we think about measurement

Ultrasonic flowmeters installation guide

-

The pipe must be completely full.

-

The sensors can be installed vertically or horizontally.

-

Use coupling gel between the sensor and the pipe to ensure the correct operation of the equipment.

Connection modes according to pipe diameter

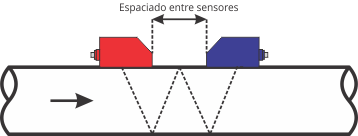

W Method: If the diameter of the pipe is in the range of 15-100 mm, the configuration you should use is W, as shown in the figure below:

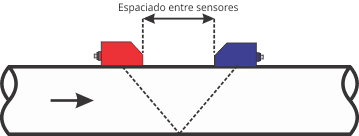

V Method: If the diameter of the pipe is in the range of 50-300 mm, the configuration to be used is V, as shown in the Figure below:

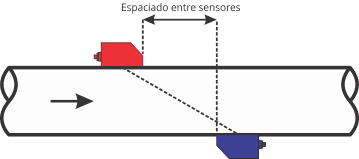

Z Method: If the pipe is in the range of 300-5000 mm in diameter, the configuration to be used is Z, as shown in the Figure below:

The spacing between sensors is a parameter given by the computer. Visit the User Manual of each ultrasonic flowmeter as appropriate

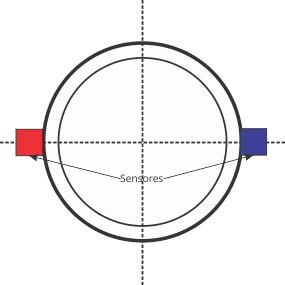

IMPORTANT: Always install the sensors on the sides of the pipe. If they are installed on top, there is a risk of making erroneous measurements due to the presence of air bubbles. For example, for a Z configuration, if we made a cross section of the pipe, the installation method would be as shown in the Figure below:

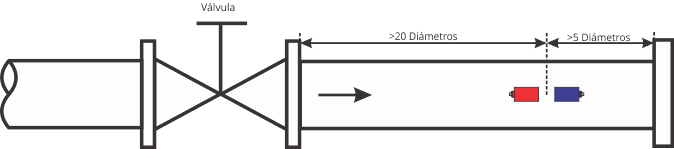

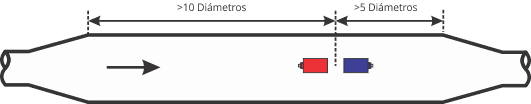

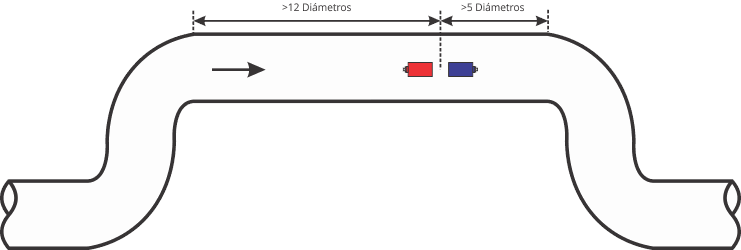

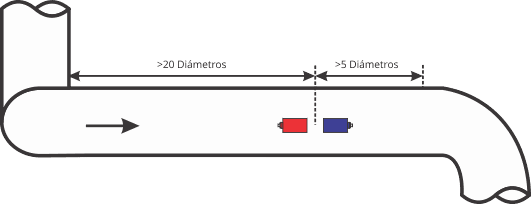

Necessary clearances

The clearances necessary according to the configuration of the pipe are detailed below to have an appropriate measurement in the use of ultrasonic flowmeters.

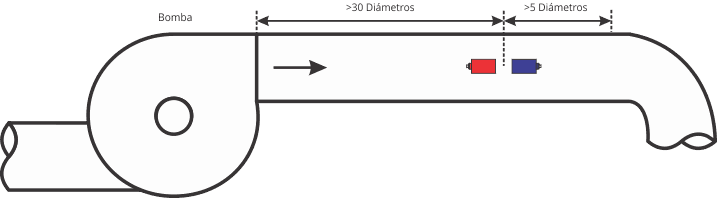

Pump at the entrance situation

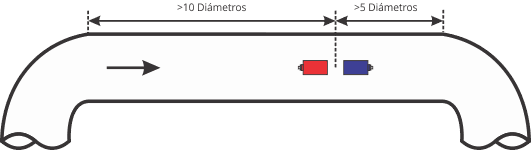

U connection ascending, descending or S situation

In this case it can be observed for the case of a descending U but it has the same clearance as the other configurations:

Pipe extension situation

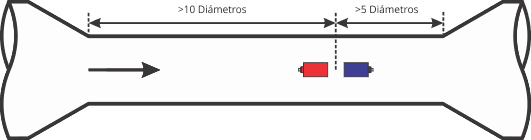

Pipe reduction situation

Elbow to elbow situation

Elbow to elbow perpendicular to the plane of the pipe situation

Valve situation